By 2050, plastics in the ocean could outweigh fish.

This is if we continue producing and consuming plastic at the current rate of 400 million tonnes every year.

And if you think most of the plastic we produce is recycled, think again. Only 9% of global plastic waste is currently recycled.

What’s more, producing all this plastic currently accounts for 4.5% of global carbon emissions. Yikes.

But for all its faults, plastic is extremely useful.

So if we must continue our plastic addiction, we need to develop cleaner and more efficient supply chains.

As it turns out, two Murdoch University PhD students at the Bioplastic Innovation Hub are using biotechnology to do just that.

GROW YOUR OWN

Currently, 98% of single-use plastics are made from fossil fuels.

Add to that their energy-intensive processing, and they have a huge carbon footprint.

One alternative to current methods is to produce bioplastics from biological feedstocks like grain.

But creating these feedstocks can be energy-intensive due to the farming involved. It can also divert resources from struggling communities.

GIPHY

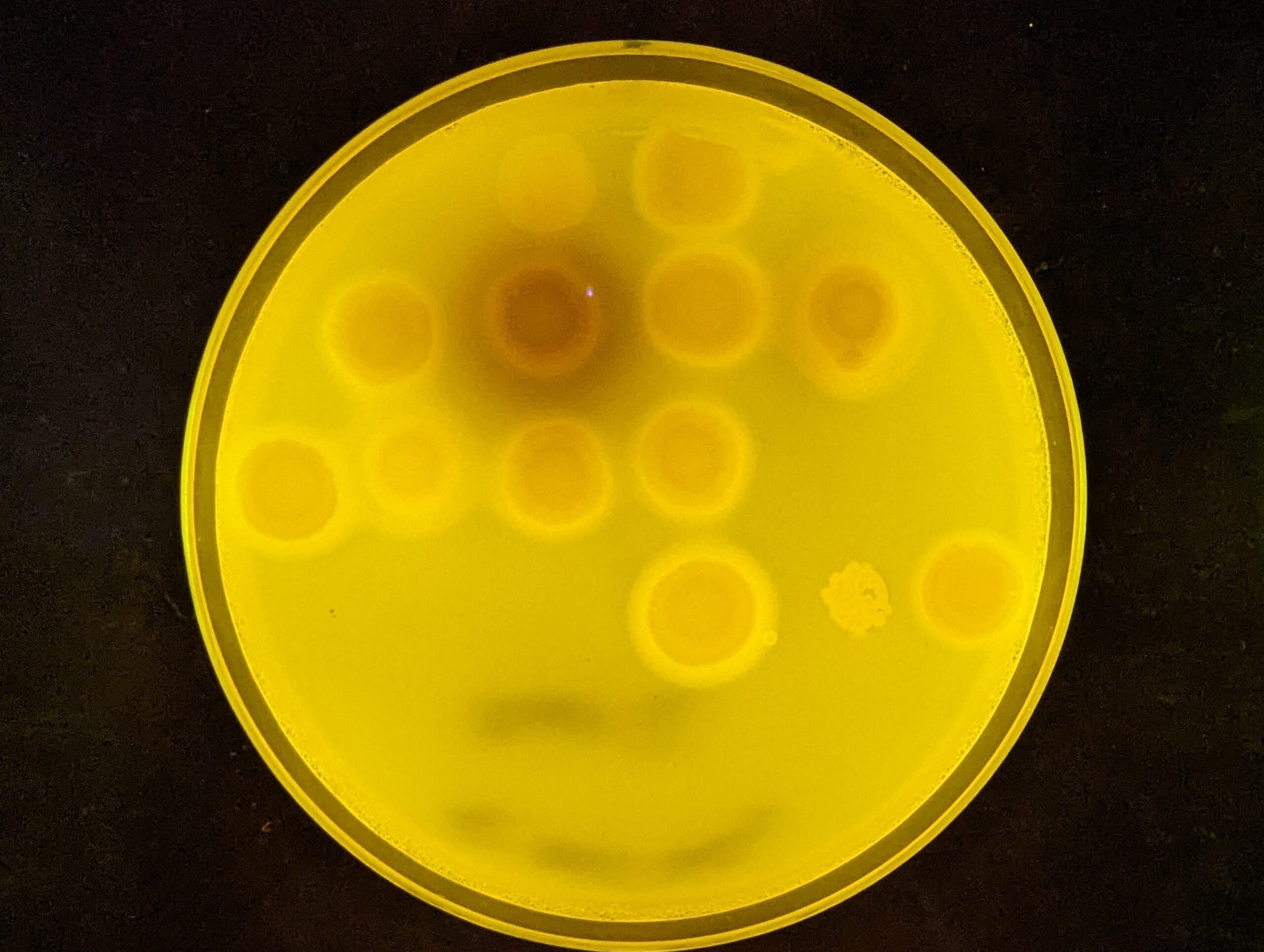

That’s why PhD student Harrison O’Sullivan is using bacteria to create bioplastic from biowaste.

“McDonald’s has half a million tonnes of waste chip oil every year,” says Harrison.

“That wasted oil could be fed to bacteria and then turned into bioplastic.”

If it sounds tricky, that’s because it is.

Plastics are made of complex organic compounds called polymers, which are difficult to make.

“We haven’t found a bacteria that can do everything from start to finish,” says Harrison.

But just because you can’t find it doesn’t mean you can’t make it. Right?

GOOD BACTERIA

Harrison uses genetic engineering to build bacteria that can turn biowaste into bioplastics.

“We’re not reinventing the wheel,” says Harrison.

“The ability to make the polymers already exists in nature.”

“We’re exploiting a natural process and re-engineering bacteria so they make very particular ratios of polymers and chain lengths.”

However, our plastic problem won’t be solved in a lab. It needs to have the right properties to work on a larger economic scale.

“We work together with chemists and polymer engineers to ensure the plastic has the right properties for the right use,” says Harrison.

THE BIG CLEAN-UP

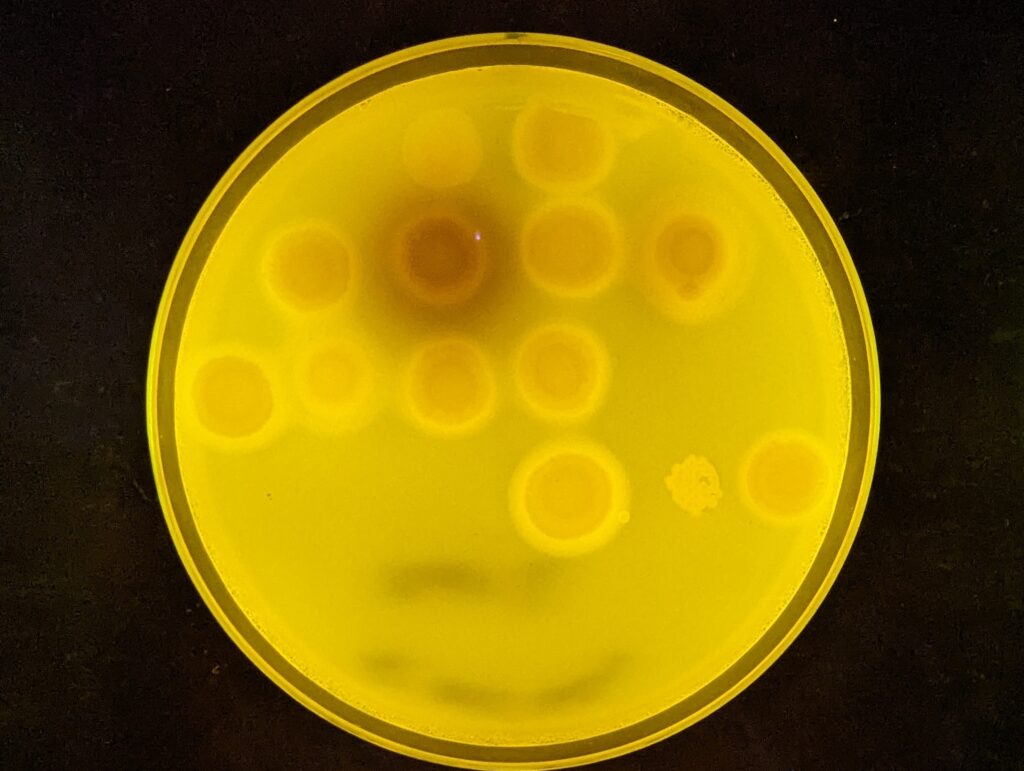

Fellow PhD student Joseph Boctor is working on ways to get rid of existing plastic pollution.

“We have to find a way to convert the problems of the past into products that could be eco-friendly,” says Joseph.

“The keyword here is efficiency.”

Like many scientists, Joseph is drawing inspiration from nature.

“One of the organisms we study is the wax moth,” says Joseph.

The wax moth is a parasite that eats beehives and honey wax.

“Honey wax is a natural plastic because it shares a very similar chemical structure to synthetic plastic polymers.”

Joseph is taking inspiration from organisms like the wax moth and using computational algorithms to genetically engineer the most efficient enzyme possible.

“With computational algorithms, you can basically predict what sorts of mutations could lead to a higher efficiency or higher degradation abilities for these enzymes,” says Joseph.

“You can even synthesise an enzyme from scratch that can degrade plastic. And by from scratch, I mean [a] completely synthetic enzyme that has no counterpart in any organism.”

While it’s early days for both these projects, this type of unconventional thinking could turn out to be a game-changer for our plastic problem – and the health of our planet.