Leather is one of our most iconic clothing materials.

From the Roman Empire’s armour to the colourful leather at Paris Fashion Week, our relationship with the tanned hide stretches back thousands of years.

But while leather holds a strong place throughout human history, making it creates a lot of waste. In Australia alone, we create 2 million tonnes of leather, textiles and rubber waste each year.

Producing leather requires land for grazing animals, producing greenhouse gases. It also takes over 100 chemicals to turn animal hide into leather.

In a bid to reduce the environmental impact of leather, manufacturers have been looking into leather substitutes.

And while synthetic leather has been around since the 1940s, most are bad for the environment as they’re made from plastics.

But a new leather substitute is on the horizon, and it’s generating a lot of interest—mushroom leather.

Mushroom for improvement

Fremantle biotechnology company Life Cykel has been finding new uses for mushrooms since 2015.

From medicines to mushroom honey, the company is always looking for new applications for the humble fungi.

Head Scientist Thomas Loussier and his team are developing their own method to produce mushroom leather.

Thomas is a self-proclaimed “mushroom missionary man” out to make the world aware of mushroom power.

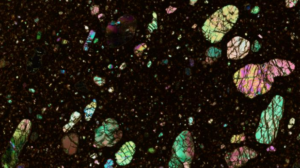

“Mushroom leather is made from the underground root structure of mushrooms—the white filament you can find underground in the forest called mycelium,” he says.

“The mushrooms we know are more like a fruit—like an apple from a tree.”

Mycelium plays a huge role in the environment. It makes up 30% of soil biomass, breaking down nutrients from rocks and decomposing plant matter.

Growing the future of fashion

Thomas believes mycelium’s unique physical properties make it a versatile choice for designers.

“What’s interesting about mycelium is it’s one cell wall thick,” he says. “In comparison, humans have five major layers of skin. That means it’s strong and has very interesting mechanical properties.”

“Its strength comes from its adaption to the extreme conditions it finds underground. It has evolved over millions of years and survived multiple extinction events.”

There are a few different ways to make mushroom leather, such as using mushroom caps instead of mycelium.

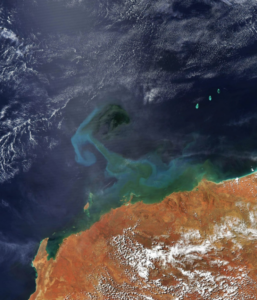

It can also be grown into the shape you need using heat and light in a nutrient bath—much like kombucha.

The energy and space needed to produce mushroom leather is also much lower. It can be grown in a few shipping containers or in “shroom rooms” in the city.

Life Cykel’s process is also ecofriendly, using sugarcane waste as the food to grow their mushrooms.

Making moolah from mushrooms

So how does a vegetable substitute stack up against the original? It all depends on how it’s treated.

According to Thomas, a mushroom leather coat can be treated with beeswax or combined with a natural fibre like cotton.

With these treatments, you can expect it to last a few years before it succumbs to wear and tear.

While less durable than traditional leather, the product is softer, more breathable and is still waterproof.

Mushroom leather is already sold in Europe, with Berlin-based ZVNDER selling wallets, hats and shoes.

Even Stella McCartney has a limited run of mushroom leather products in her range.

No Australian companies offer mushroom leather in their catalogues yet.

While startups are embracing this mushrooming industry, only time will tell if a fungi jacket will grow on you.