Bridges are more than connections.

Designing and constructing these impressive structures requires science, mathematics, creativity and innovation, which requires a team of experts to execute.

STURDY AS SHE GOES

The first step in building a bridge is the design phase.

Much like the spaghetti bridges made by school students, creative designs need to be tested by physics.

A handful of bridge types have stood the test of time, including arch, beam, cantilever, suspension and truss bridges.

Each looks different but all rely on balancing tension and compression forces to stand the test of time.

Credit: Chris Briggs via Unsplash

Nature is often a bridge’s biggest challenge, with natural disasters like earthquakes and floods threatening its structural integrity.

Other unpredictable events can put that integrity to the test – like when a container ship crashed into the Fremantle rail bridge during a storm in 2014.

The complexity of a bridge is why a team is needed to get a concept off the ground.

A TEAM EFFORT

Building a bridge takes more than steel, concrete and people in hard hats.

These engineering masterpieces rely on a wide range of skills to create the perfect balance of physics and beauty.

“Bridge projects bring together a wide range of STEM professionals,” Engineers Australia’s Chief Engineer Katherine Richards says.

“These include geotechnical engineers, materials scientists, hydrologists, surveyors, project managers and digital design specialists.”

Credit: Daniel McCullough via Unsplash

Katherine says engineers are involved in every stage of a bridge’s life, from planning and design to fabrication and construction.

“Each of these roles bring focus to a bridge being safe, sustainable and fit for purpose throughout its design life,” says Katherine.

“Bridges are among the most rewarding projects for engineers to be involved in because they combine technical challenge with tangible community benefit.

“Each bridge improves connectivity – linking towns, regions and people – and may become a local landmark.”

NOT BAD, GOOD SIZE

While construction may be complex, a completed bridge can be a wonder to behold.

Earlier this year, the Cross Bay Link bridge in Hong Kong was named the city’s most popular piece of infrastructure from the past 25 years after winning a public vote.

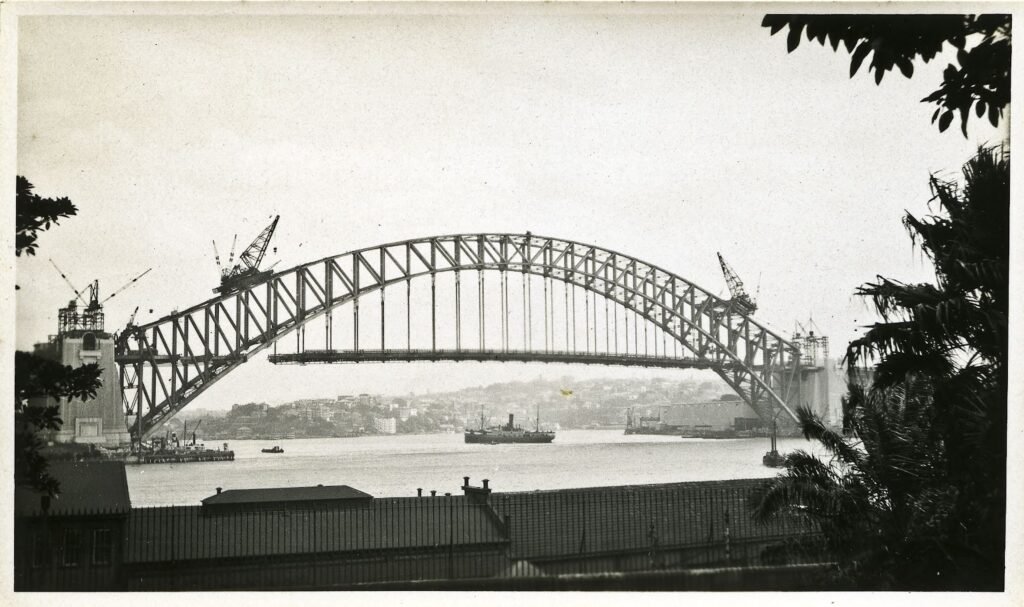

Closer to home, the Sydney Harbour Bridge is a globally renowned landmark.

Innovative for its time, the bridge took 8 years to go from concept to opening in 1932.

Its construction was an impressive feat, with the two arches built from opposite sides of the harbour before meeting perfectly in the middle.

Credit: City of Sydney Archives

The Sydney Harbour Bridge is now one of the country’s biggest tourist attractions. More than 4.5 million people have climbed to its top since 1998.

In WA’s own backyard, the Narrows Bridge in Perth might seem standard, but it’s three bridges, all built at different times, rolled into one.

The original road bridge was built in 1959, was extended to the west in 2001 and had a railway bridge added to the middle in 2007.

Extending and widening existing bridges are common, but sometimes an entire bridge needs to be replaced.

Credit: Mason Kimbarovsky via Unsplash

This is currently happening at the Fremantle traffic bridge, where a new bridge is being built while the existing one remains open.

And while the roadworks might be frustrating for road users, the new bridge is expected to be safer and improve traffic flow when it opens in 2026.

The Fremantle Bridge was once entirely made of wood – a common occurrence in Australia.

“We have about 27,000 timber bridges here in Australia and more than 2,000 of them are in Western Australia,” says Professor Abhijit Mukherjee from Curtin University.

“They were built because we didn’t have steel – it was too heavy to import – while jarrah trees were available.

“That is something that is quite special for Australia.”

MODERN MATERIALS

Modern technology is helping to build more sustainable bridges using innovative materials.

Australian researchers are experimenting with self-healing concrete containing microcapsules capable of repairing cracks, to help structures last longer.

Credit: Dominik Kollau via Unsplash

New sensor-based technology in what’s known as smart bridges can detect early signs of damage, allowing maintenance crews to fix problems before they worsen.

In the Netherlands, engineers are even exploring the use of 3D printing to build bridges, which could reduce costs and the amount of material needed.

As innovation continues, the roles needed to build the bridges of the future will only grow.

“Every project, especially infrastructure projects like bridges, help shape the way people live and connect,” says Katherine.

“Future bridges will not only be stronger and longer lasting but also smarter, integrating sensors, real-time monitoring and adaptive materials.

“It’s an exciting time to be part of the engineering profession.”