Imagine a fully automated 3D printer suspended in mid air, churning out crucial components for use at home and abroad.

Sounds like science fiction? Think again.

In-space manufacturing – sometimes called in-orbit or off-Earth fabrication – is a booming industry.

Of the three major types, space-for-space describes things made in space for use in space settings.

Like the International Space Station, which, being larger than a soccer pitch, had to be pieced together in-orbit.

The second type, space-for-surface, is where things are made in space to be used on other planetary bodies, like Mars or the Moon.

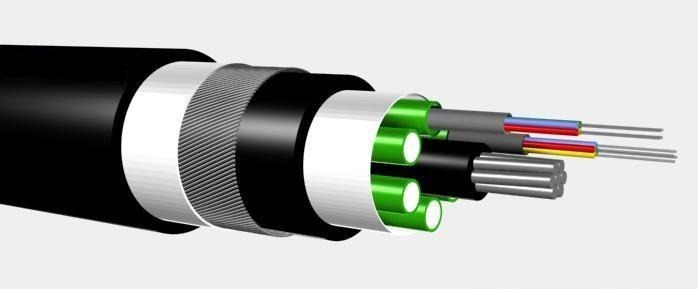

The third – and most exciting – is known as space-for-Earth. These objects are made in orbit to be used on Earth. Everything from pharmaceuticals to fibre-optic cables can be made this way.

Space-for-space and space-for-surface will be fascinating in the future, but space-for-Earth is where fascinating things are happening now.

Credit: Mike Winkelmann (CC BY 4.0)/Wikimedia Commons

Why the long space?

Three major elements of space make it perfect for fabrication: vacuum, low temperature and microgravity.

Microgravity is the weakened force of Earth’s gravitational pull as you travel further away.

“In space, we have microgravity, which prevents mixing by natural convection,” says Professor Volker Hessel, a space resource and chemical engineering expert at the University of Adelaide.

Despite the name, this is the weightless quality of space. ‘Zero gravity’ is a misnomer, as a small amount of gravity can be detected everywhere in space.

Microgravity provides a rare and useful working environment for scientists.

Volker says that, on Earth, “medicinal investigations use tissue as an experimental medium”. But this is easier to do in space.

“In microgravity, the tissue is more expanded because there is barely any gravity,” says Volker. Meaning experimental tissues can grow with fewer restrictions and give more meaningful results.

“Here on Earth, our cells are compressed,” says Volker. “Even though we don’t feel it, and when fluid goes through, it has to push against gravity all the time.”

Earth-based labs spend millions attempting to replicate these conditions. One start-up offers researchers microgravitational experiences for a measly $460,000.

Funnily enough in space, it’s the status quo.

A galaxy not so far away

Some claim almost any industrial process will be more efficient and affordable in space than on Earth.

Nanomaterials, crucial alloys, hyper-specialised semiconductors and many other things will one day be made in space.

Volker says creating small amounts of high-quality materials in space is the future for space-to-Earth manufacturing. However, he says growing large amounts of materials in space for use on Earth is yet to make economic sense.

Fiber-optic cables, the circulatory system of the modern world, are of the highest quality when manufactured in microgravity. In fact, they’re being made on the International Space Station right now.

Credit: Srleffler (CC BY-SA 3.0)/Wikimedia Commons

“Economically, the optical fibres make perfect sense,” says Volker.

It’s not just fibre-optic cables. A company called Varda recently crash-landed a space-made HIV/AIDS medication in one of South Australia’s vast deserts using this technology.

Manufacturing these drugs on Earth requires such expensive machinery that costs skyrocket, potentially making the medication inaccessible to those who might need it.

It’s a challenging space

In-space manufacturing utilises automation and advanced 3D printers.

Recent advances in AI and machine learning represent new and exciting possibilities, such as space-based vertical farms.

But Volker says the compactness of space manufacturing will also present new challenges.

“Say there’s a disease outbreak, which can happen in a vertical farm. How can we manage to solve that?” asks Volker.

Credit: ifarm.fi (CC BY-SA 4.0)/Wikimedia Commons

Other issues like maintenance costs, long-term viability, the accumulation of space junk and who pays space taxes all warrant serious thought.

Unfortunately, none of these problems have simple answers.

For now, in-orbit manufacturing is paving the way for all sorts of techy, spaced-out inventions, the likes of which we can hardly imagine.