Spinifex Brewing Co. is a local brewery focused on craft beers infused with native Australian flavours like lemon myrtle leaf, Geraldton wax flowers and gubinge.

They’ve recently teamed up with Murdoch University’s Harry Butler Institute to recycle their brewery waste using locally sourced algae.

THE BEER NECESSITIES

Before we unpack the finer details of reducing brewery waste, let’s recap how beer is made.

Brewing uses a few simple ingredients: water, malted grains (such as barley), hops and yeast.

The yeast allows for fermentation to occur, which produces alcohol and carbon dioxide. Once the brewing process is over, the leftover yeast becomes waste.

That’s where Dr Navid Moheimani comes in. He’s the director of algae research and development at the Harry Butler Institute Centre for Water, Energy and Waste.

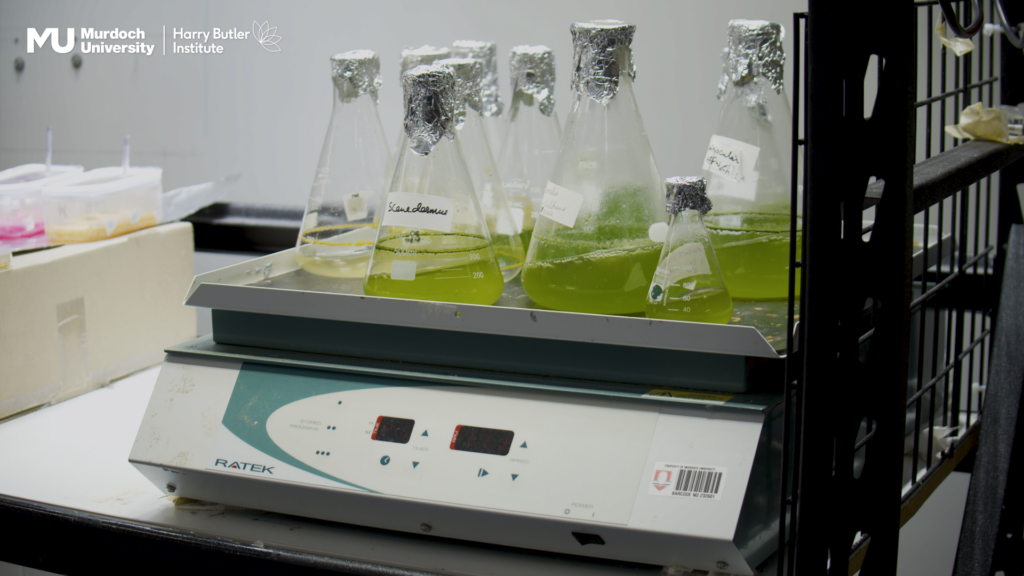

Navid and his team have developed a new process that uses algae to turn beer waste into a protein-rich biomass.

They hope to sell the biomass as animal feed and – one day – as burgers and pasta.

The process is also carbon neutral. In fact, every kilogram of the algae absorbs 1.8 kilograms of carbon dioxide from the air.

HOPS AND DREAMS

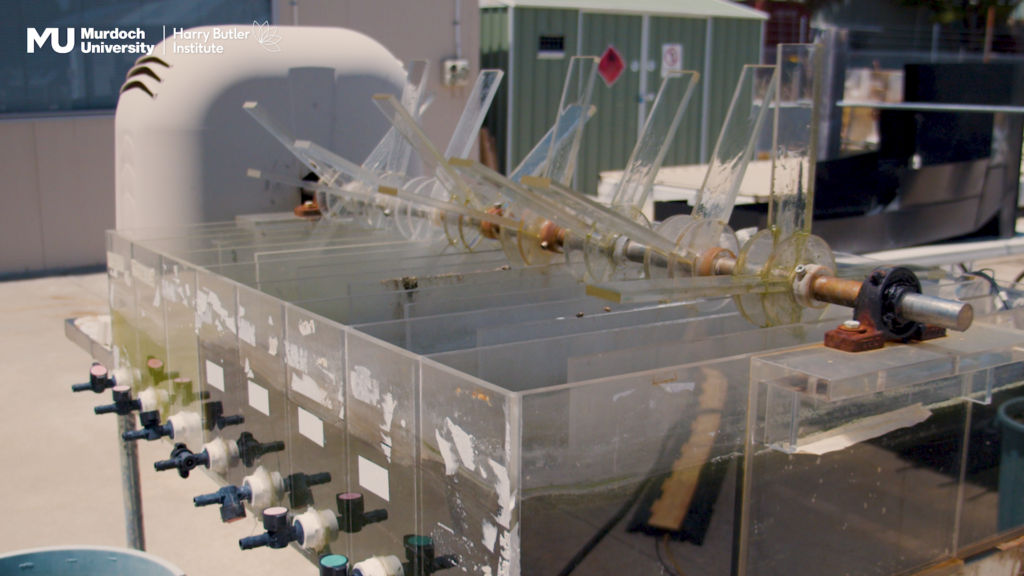

Based at the new state-of-the-art Food Innovation Precinct WA near Mandurah, the project has been years in the making.

“It took us almost six years to come up with the species of algae that can treat the organic wastes produced in the brewery,” says Navid.

The biggest challenge is finding a way to remove the caustic element from the waste stream.

In general, the waste undergoes anaerobic digestion before algal treatment. This creates methane gas which can be burned to fuel the whole system – reducing electricity costs.

“The economics are extremely important in what we do,” says Navid.

“We always have that vision, and we always look at the economics of the process.”

Once the protein-rich biomass has been removed, the leftover water can be used for irrigation.

In theory, this wastewater could even be treated for human consumption.

“Recycling water is critical for sustainability,” says Navid.

ALE YEAH!

To make things even better, this process can be applied to other streams of organic waste such as those from an abattoir. However, each type of waste requires its own specific species of algae.

Western Australia’s strict quarantine laws mean the algae must be born and bred within the state. Luckily, the state’s sunny and dry climate makes for an ideal location to mass cultivate algae.

From the thousands of local species isolated by Navid’s team, three or four species can be used to treat organic effluent.

A GOLDEN HOPPORTUNITY

For Spinifex Brewing Co., this project is an opportunity to improve the environmental sustainability of its operation.

“With the support of Murdoch University, we want to create a circular economy and turn waste into profit,” says Steve Jansen, Export Manager at Spinifex Brewing Co.

“We like to say we’re saving the planet one beer at a time.”

While it’s early days yet, we’ll raise a glass to that.

*Correction: An earlier version of this article stated: “The biggest challenge was finding a way to remove the caustic element from the spent yeast.” This was corrected on 23 August 2023 to state: “The biggest challenge is finding a way to remove the caustic element from the waste stream.”