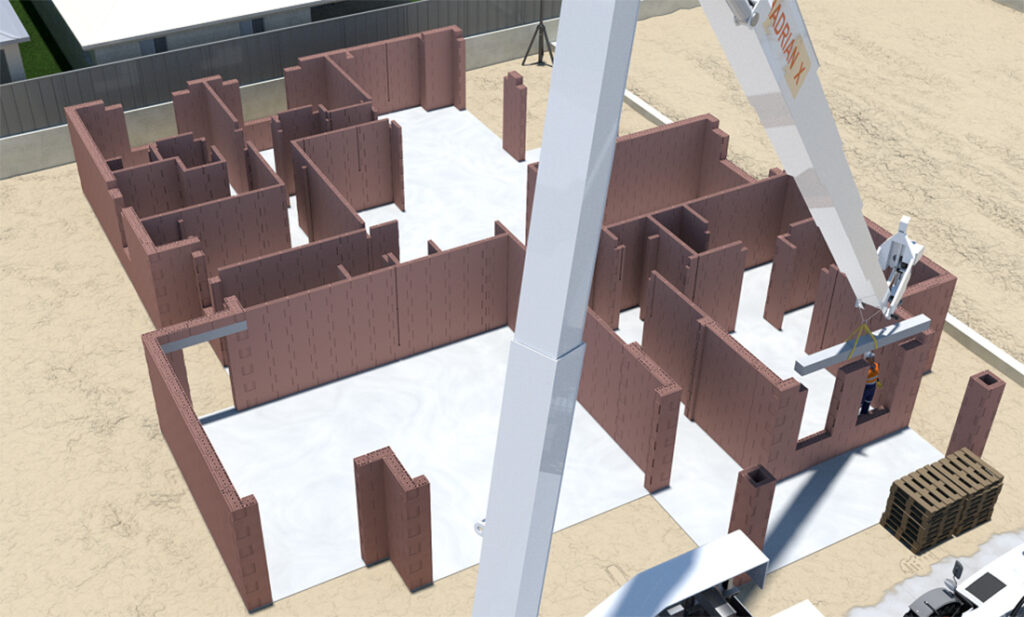

Fastbrick Robotics is responding to the increased demand for housing and a shortage in skilled construction labour with a bricklaying robot.

The gigantic robot Hadrian X, equipped with specialised technology, can lay a residential house from the ground up, on site, in 2 days.

It’s the first end-to-end construction robot in the world, and Fastbrick CEO Mike Pivac is confident it will revolutionise the industry. We chatted with him to find out more.

Precision, precision

Hadrian is not the first large-scale industrial robot that can complete a whole build from start to finish. It’s not even the first outdoor construction robot.

What’s remarkable is it’s both.

“Anything you can build inside a factory … we’re getting really, really good at,” Mike said. “Trouble is, nothing’s happening outdoors.”

That’s because environmental factors like wind and temperature variations can make life difficult for robots outdoors.

Most robots can’t adjust to small, quick changes in wind or temperature fast enough to keep up.

That’s fine if little wobbles won’t make a big difference. But when you’re working on something as large-scale as building a house and a light breeze could lead to bricks being laid way out of position, it can get very dangerous.

So up till now, any robot building on such large scales had to be indoors in minutely controlled environments.

Hadrian has overcome this problem using the precision technology Dynamic Stabilisation Technology (DST). DST was developed in Perth by Mike’s cousin, Mark Pivac, back in the early 2000s. The computer program measures environmental factors an astounding 2000 times per second, then accounts for them in real time.

Combine that with a 3D printer style build process based on CAD modelling, and you get a robot that can lay bricks with an error margin of just 1 millimetre. An experienced brickie could lay with this accuracy, but only with a whole lot of careful measurements and a steady hand.

Cheap, but not nasty

Hadrian’s got other things going for it than just accuracy though. It’s also 15 to 20 times faster than human builders, and the use of CAD modelling reduces waste because every brick is planned and calculated.

Plus, it’s safer. It eliminates the need for humans to work at height and in intensive labour exposed to the elements. Mike seems particularly proud of this.

“We’re … helping people transition into smarter jobs, safer jobs. Jobs that people can actually work in until they retire,” he said.

Together, these aspects should lead to vastly reduced housing costs. Not only is this great for first-home buyers, it’s also a potential solution to housing demand worldwide. Mike calls it a “social housing solution” that will produce high-quality, affordable housing for a growing worldwide population. With a rate of about 20% of the global population currently without adequate housing, there’s a clear need.

Highs and lows

Fastbrick’s technological innovations may be groundbreaking, but that doesn’t mean it’ll all be smooth sailing. Bricklaying is an old industry—as old as the oldest cities we know of. The first brick structures were made in Jericho around 7000 BC. In terms of technique, there’s not a lot to change.

As Mike pointed out,

“There’s not been a change in the way we lay a brick or block in 5000 years ... and now we’re proposing that there is ... we’re going to see things change in a very big way, very fast.”

After 5000 years of doing the same thing, such a big shake-up is sure to be met with some resistance. But any resistance and challenges faced by Fastbrick Robotics are more than offset by the potential rewards.

One of the best things about being the CEO of Fastbrick, according to Mike, is that “everybody wants this to work … it’s an amazing thing to work in an organisation where you have global support to be successful”.

The Hadrian X has the potential to change how the housing industry works, and it was invented right here in WA. Keep an eye out for this exciting company to be making big waves and big buildings in the near future.