Global food security is under pressure from climate variability, population growth, economic shocks and disease outbreaks.

Closer to home, we’ve all felt the pinch. Remember when floods wiped out lettuce crops and KFC replaced iceberg lettuce with cabbage in its burgers? Or when bird flu sent the price of eggs soaring?

Add in fragile supply chains and a food waste crisis, and keeping food on our plates isn’t as simple as it sounds.

To keep us fed, a farmer must be a jack of all trades and a master of science. So what does science look like out in the paddock?

LOOK MUM, NO HANDS!

Driverless cars have been the subject of science fiction and hype for decades. But for farmers across WA, autonomous tractors have been a reality since the mid-2010s.

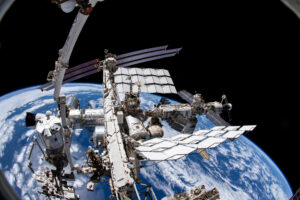

Autosteer technology – guided by GPS satellites – allows farm machinery to precisely seed and harvest crops like wheat, barley and canola. Self-driving tractors improve time and resource efficiency.

Mingenew wheat and sheep farmer Rob Holmes says they are precise.

“There’s a GPS receiver on the roof of the tractor,” says Rob. “It is a bit fancier than the one in your car, but it’s the same idea – it knows where you are, down to about a metre.”

While that’s accurate enough for general navigation, satellites can drift a little. Small errors add up quickly in agriculture. That’s why many farmers add a base station on their farm – an immobile GPS anchor.

Credit: Kate Holmes

“The base station is always talking to the tractor, sending those correction signals. If the tractor drifts even a little, the autosteer corrects it straight away,” says Rob.

“That’s how you get it down from a metre to just a few centimetres.”

“It’s how you get those neat, dead-straight lines across the paddock.”

Being a few centimetres off sounds minimal. But when you’re seeding, spraying or harvesting crops across hundreds of hectares, those errors multiply.

It’s like painting the same patch of wall twice or missing a strip when mowing the lawn – but multiplied hundreds of times over.

Autosteer technology has changed the way WA farmers work, growing crops on the same amount of land more efficiently. This means less wasted crop space and more food grown – and stronger food security for all of us.

I SPY WITH MY LITTLE AI

While satellites are used to steer tractors remotely, AI plays a role too – by helping farmers inspect their grain one wheat kernel at a time.

Before grains can be made into sourdough, beer or oil, they must be thoroughly checked for diseases and defects.

Co-operative Bulk Handling (CBH) receives millions of tonnes of grain from across WA. CBH grades the grain when it is received, which determines how, when and where it can be sold.

Defects like sprouted grain, field fungi and frost damage all affect a truckload’s final grade.

Carrying out visual checks for defects is a manual process undertaken by grain samplers, hundreds of times a day.

Enter CBH’s new visual analysis grain sampler. This machine was developed in collaboration with Deimos.

“The great thing about the technology is we can analyse half a litre of grain in around 2 minutes,” says Craig McLure, Head of Grain Technology at CBH.

The printer-sized machine scans thousands of grain kernels from both sides.

The device moves the grain onto glass plates, which vibrate to ensure grain is evenly spread.

Credit: Supplied CBH

Craig says high-resolution cameras photograph each kernel from the top and bottom.

AI software then compares each individual grain against thousands of reference images. The AI looks for signs of damage, disease or contamination that would otherwise take a trained eye time to spot and count.

“The machine effectively deploys our very best sampler to every sample site in our network,” says Craig.

The visual analysis machine is not just about speed. By catching defects early, it protects the quality of food on our shelves, in our kitchens and on our plates.

FROM LITTLE THINGS, BIG THINGS GROW

Farming isn’t one kind of science: it’s all of them.

After all, the full saying is “jack of all trades, master of none; is often better than a master of one”. In agriculture, wearing many science hats serves one goal: putting food on the table.

CBH Group supported the development of the new Global Food Solutions exhibit – part of Scitech’s Here, There and Everywhere permanent gallery transformation. The exhibit opened on 22 September.