Humans have been drinking milk for around 10,000 years. In all that time, the way we process milk has changed a lot.

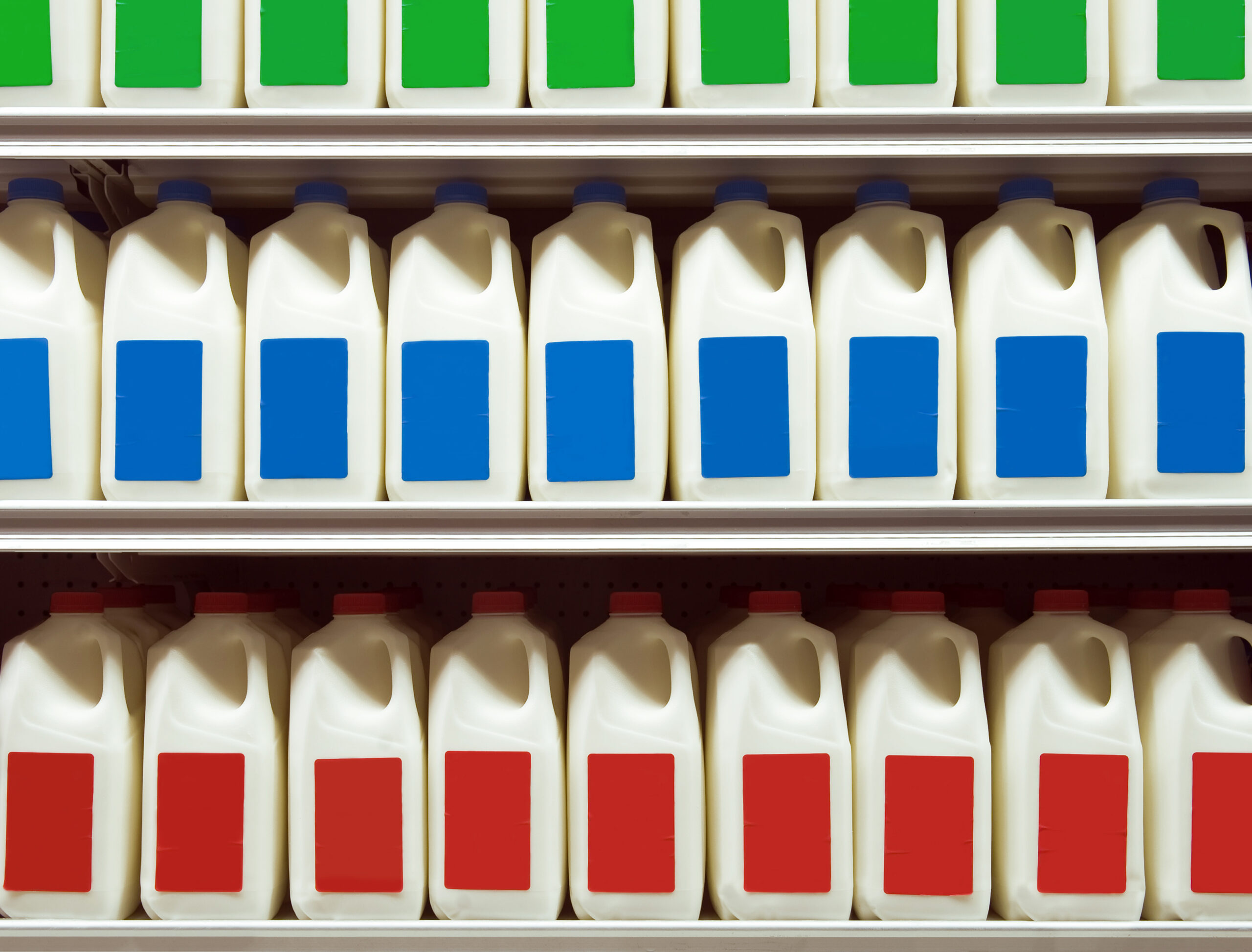

And different processing means different labels.

About 87% of milk is water. The remainder is a mix of proteins, fats, vitamins, minerals and carbohydrates – including the infamous lactose.

Food Standards Australia & New Zealand states that “full cream” milk must consist of at least 3% protein and 3.2% fats. However, the amount of protein and fat in a single cow’s milk can fluctuate over time. To even out these changes, dairy processors mix together the milk of many different cows.

Hot N Cold

It takes a fair bit of time for milk to reach our supermarket shelves. And it just so happens that raw dairy milk is a great place for bacteria to grow. Not exactly the most ideal combination, which brings us to pasteurisation.

Pasteurisation is the process of killing harmful bacteria in raw dairy milk by heating it to 72°C for 15 seconds. The milk is then cooled down very quickly to stop the heat from changing the flavour and nutritional value.

GIPHY

So when you see ‘pasteurised’ or ‘unpasteurised’ on your milk label, it’s signifying whether it’s been treated by heat or not. But wait, there’s more.

Long-life milk (aka UHT) is heat treated at an ultra-high temperature of 140°C for 2 seconds, killing off even more bacteria. The process also reduces the number of enzymes that can spoil the milk. As a result, the milk can be stored in a sealed container for up to 6 months.

Under Pressure

Over time, the fats globules in the milk start to clump together and rise to the top, giving the ‘cream on top’ effect. This isn’t always desirable. Not everyone likes drinking straight cream on Monday and watery milk on Friday!

To prevent the ‘cream on top’ effect, dairy milk is homogenised. During this process, clusters of fat are broken up by spraying the milk through high pressure nozzles. The smaller clumps of fat can then be suspended evenly throughout the milk, making for a more consistent texture and taste.

GIPHY

Skinny love

Some people prefer the low-fat life, and that’s where skim milk comes in. In Australia, skim milk can’t be more than 0.15% fat.

Historically, producers waited for the fat to rise and skimmed it off the top leaving ‘skimmed milk’. Nowadays, they use centrifugal separation.

During this process, full cream milk is spun around really fast to force the fat to separate from the skim milk.

A whole new world

Continuous innovation in industrial technology has allowed for many products to be made from a simple starting point like raw dairy milk. The above is by no means an exhaustive list. Believe it or not, there are other types of dairy milk!

And don’t even get us started on non-dairy milk.

GIPHY